咨询热线:

0769-22805355

电话:0769-22805355

手机:15989900139

邮箱:dgyuyong@263.net

地址:东莞市南城区三元里公寓2号楼A栋写字楼四楼401室

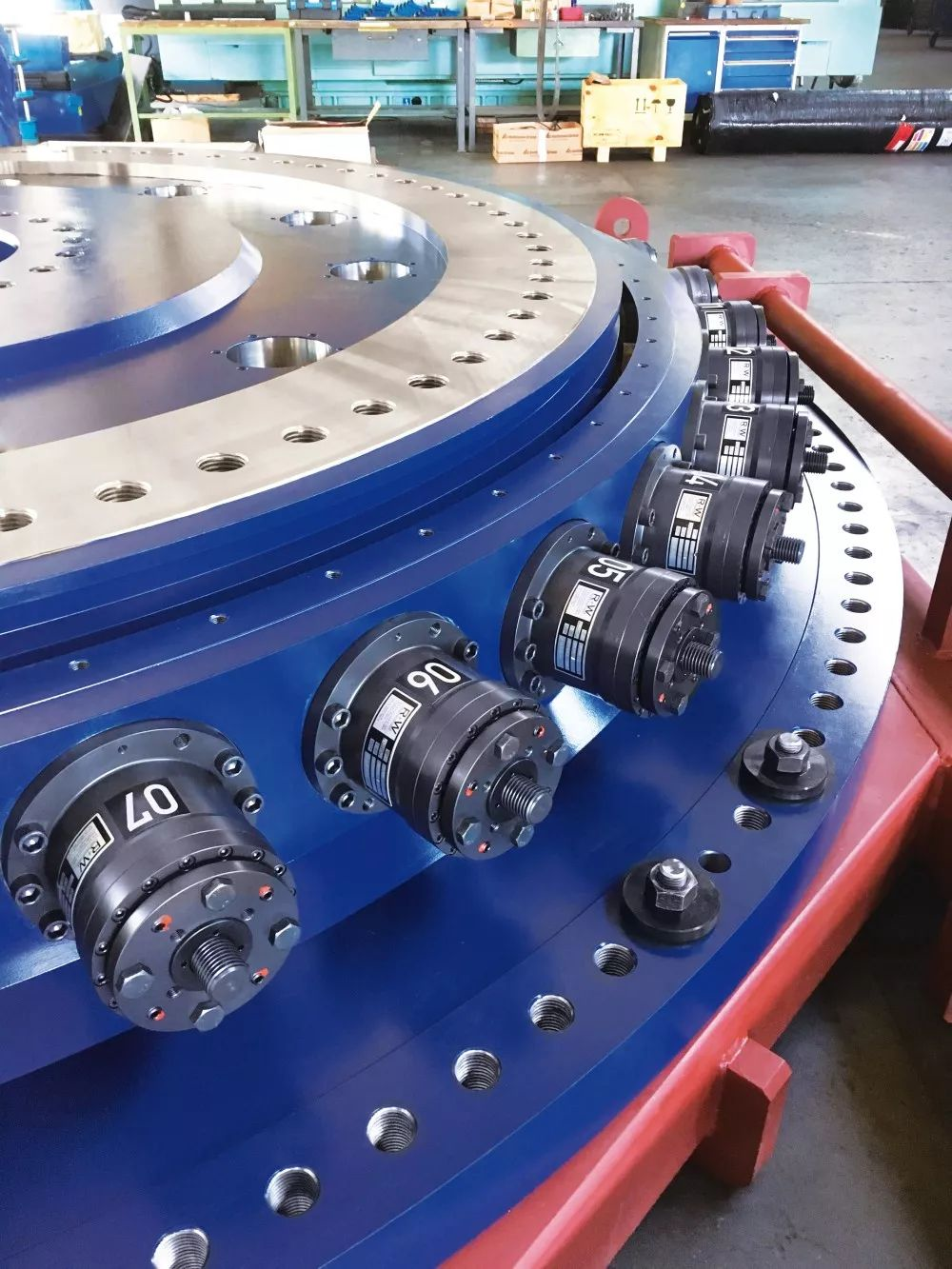

R+W 新研发了一款XXL超大型号的安全型联轴器,可用于风能测试设备。此项应用正在申请吉尼斯世界纪录。

R+W has developed an XXL safety coupling for use in a wind energy test facility. An application is currently pending for this to be included in the Guinness Book of Records.

安全型联轴器在保证转动设备顺利运行的过程中起到决定性的作用。它们可保护精密的机械部件不受过载损害。过载损害不仅意味着花费昂贵的修理费用,也意味着长时间的机器停机。当机器因为故障而停机时,时间将会一分一秒地流失。安全总是放在第一位——因此,当我们在选择和应用安全型联轴器的时候,精准和专业的知识都是非常必要的。

Safety couplings are a decisive factor in guaranteeing seamless operation in rotating equipment. They protect delicate machine components from overload damage which can lead not only to expensive repairs but also to extensive downtime. Every millisecond counts when shutting a machine down due to failure. Safety first – expert knowledge and precision are therefore required when selecting and applying safety couplings.

研发特殊订制的精密型和工业型驱动联轴器是 R+W 每一天的日常工作。因为 R+W 在传动发展领域的经验和专业,每天我们都会收到来自企业和科学领域各种各样详尽的询问,有的还是一些极端参数。这其中包括一些知名的项目研究。例如安全型联轴器如何应用于国际空间站,盲维护系列的金属波纹管联轴器如何应用于大型强子对撞机 The Large Hadron Collider(LHC)——现在世界上最大、能量最高的粒子加速器。

Customized manufacturing of precision and industrial drive couplings is part of the day-to-day business at R+W Antriebselemente GmbH. The German-based company regularly receives inquiries from the business and scientific communities with immensely detailed, often extreme parameters, due to the reputation for experience and expertise the in-house development department has earned it. This includes well-known projects such as safety couplings for the International Space Station (ISS) and blind-mate metal bellows couplings for the world’s largest machine and most powerful particle accelerator, the Large Hadron Collider (LHC).

高要求激发创造力

另一个旗舰项目已经在2017年的夏天成功完成安装——STF/20000。它是目前世界上最大的安全型联轴器,重达21.5吨。研发过程需要在每一方面都做到最高要求。这个项目来自于一家西班牙的联轴器制造商,他们正在研发可应用于一款丹麦新型风能测试设备中26兆瓦电动机的传动轴上。由于此款安全型联轴器是以手动复位的形式,所以需要额外的过载保护,同样也必定需要专家和合作伙伴的帮助。所以,R+W 是唯一一家能够满足此特殊需求的联轴器制造商。项目已经在2016年的7月正式开展研发。

Extreme demands generate creativity

Another flagship project was completed and installed in the summer of 2017 – the STF 20,000, which is currently the largest safety coupling in the world, weighing in at 21.5 metric tons. The demands were therefore extreme - in every respect. The order came from a Spanish coupling manufacturer which was building a transmission shaft for two six megawatt motors at a new Danish wind energy test facility. The additional overload protection required here in the form of a safety coupling with manual engagement definitely needed the help of a specialist partner. R+W was the only manufacturer that could fulfil this special requirement, and was able to start development in July of 2016.

R+W 德国的技术经理 Rainer Benz 解释道:“我们的设计规格和风力机运转的巨大负载周期对应,扭矩也可相应地达到千牛米的范围,结构规格也是按照西班牙标准。”这意味着这款安全型联轴器可支持脱开扭矩在15,000千牛米到20,000千牛米的范围之间。而通常来说,安全型联轴器的脱开扭矩最高可达2,800牛米,所以这相当于增加了7000倍的脱开扭矩范围,联轴器外径需达到4米。对于这款超大型联轴器,它的内径却仍然为70厘米,总长度为470毫米。Rainer Benz 补充道:“STF/20000 和我们其他工业型联轴器的生产原理一样,只是它并不是一个标准规格。

“Our design specification corresponded to the combination of the enormous load cycles from the action of the wind turbine, the correspondingly high kilonewton meter ranges which had to be overcome, and the structural specifications from the Spaniards,” explains Rainer Benz, Technical Director at R+W. What this actually means is that the safety coupling is designed to support a disengagement torque of between 15,000 and 20,000 kilonewton meters. Typical safety couplings offer disengagement torque levels of up to 2,800 newton meters - so this corresponds to a 7,000-fold increase in the usual value. The required outside diameter was four meters. The inside diameter of this gigantic safety coupling was still to be only 70 centimetres, with an overall safety coupling length of 470 millimetres. “The STF 20,000 is constructed using the same principles as all our other proven industrial safety couplings, but in non-standard dimensions,” continues Rainer Benz.

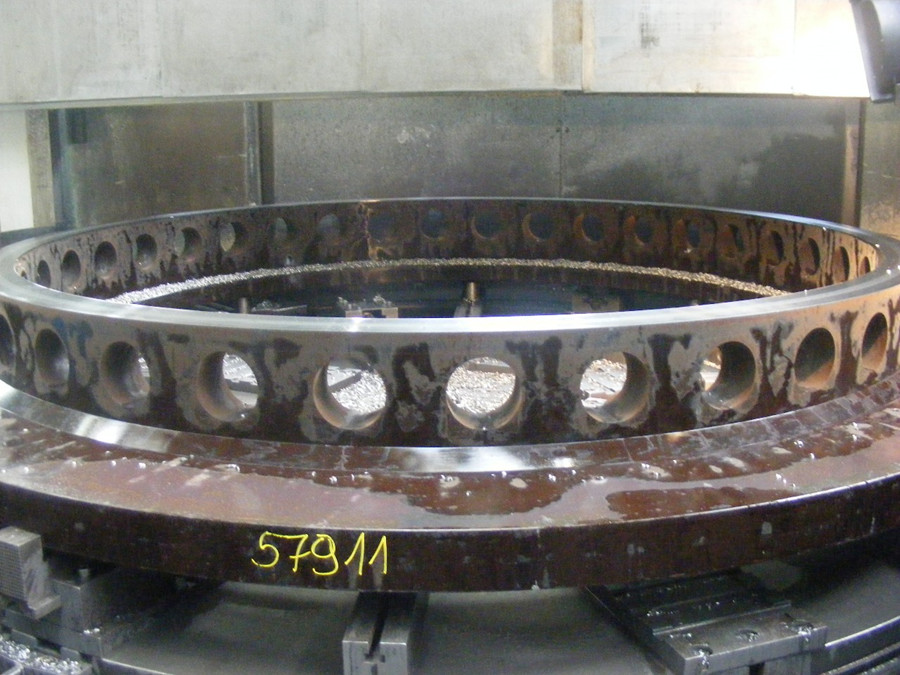

七个月的设计工作

在密集的七个月设计工作之初,R+W 的研发团队首先开始制作3D模型。工程师使用有限元分析方法去计算未知的物理参数,同时也非常关注联轴器中可能存在的缺陷,这些缺陷一般不会出现在常规使用中和标准规格中。Rainer Benz 强调:“我们非常仔细地检查风能测试设备中由于极端负载而产生的联轴器变形或裂纹。它是否能够长期地安全运行全部取决于此。”因此,为了防止磨损而导致的设备故障,设计师也格外强调了这个具体的关键点。

Seven months of design work

At the start of the seven months of intensive design work, the R+W development team approached this special task initially by producing a 3D model. The actual gigantic coupling was based on this virtual prototype. The engineers also used finite element methods to master the unfamiliar physical parameters. Great care was taken over finding possible weaknesses in the coupling which would not usually occur in conventional use and standard sizes. “We have been extremely meticulous in checking for the danger of deformation or cracks due to extreme loading in the wind energy test facility. The long-term functional safety of the coupling depends on this,”adds Rainer Benz. The designers therefore strengthened specific critical points in the coupling in order to prevent failure due to wear.

三个星期致力于解决巨大难题

在此之后,联轴器中所有的部件都作为特殊生产测试运行。在这项测试的过程中必须保障绝对精密,所有部件组装在一起时决不能容忍一丝一毫的误差,甚至是钻孔的位置。研发团队在距离德国阿莎芬堡市 (Aschaffenburg) 的门布里斯镇 (Mömbris) 50公里处租了一个生产基地,专门用来组装超大型联轴器,且面积足以容下起重机来组装。三位 R+W 的工程师花了三个星期的时间来完成此项艰巨的任务。联轴器零部件并没用从各个方向组装,而是从一个方向组装。Rainer Benz 回忆道:“由于技术需要,因此联轴器的零部件要像堆积披萨一样在同一时间放在底座上——这是一次成功的组装过程。”研发团队还用延时摄影记录下了这一激动人心的过程。

Three weeks working ona giant jigsaw puzzle

After that, all of the individual parts of the coupling were forged as a special production run. Absolute precision was required in this work as the subsequent meticulously planned process of putting the parts together would not tolerate even the slightest inaccuracy in the location of a drilled hole. The project team rented a production space 50 kilometers away from Mömbris at Aschaffenburg, specifically for the assembly of the giant safety coupling, as an especially high ceiling was needed to accommodate the large diameter of the safety coupling and the cranes used to handle it. It took three weeks for three R+W engineers to complete this giant jigsaw puzzle. Instead of assembling the parts from all sides, the individual components were mounted from one face only: “We made a virtue of the technical necessity and used the idea of stacking of a pizza as our template. Individual parts were therefore placed on the base frame one at a time - the ideal procedure as it transpired,” recalls Rainer Benz. The team also documented this exciting process using time-lapse photography.

STF/20000 被送往西班牙的安达卢西亚区 (Andalusia) 进行最后的组装,这对于物流运输又是一次巨大的挑战。这个重达21.5吨的安全型联轴器还需在运输过程中加上重3.5吨的运输架。一旦准备装运,装载机没有足够的宽度来承载这1,500公里的运输旅程。由于法国不允许高速公路进行此类重载运输,运输司机花了三天的时间才到达目的地。经过一系列密集的功能测试之后,联轴器将被运往丹麦安装在风能测试设备中,并保护设备不受损害。

The STF 20,000 had to be sent to Andalusia for final assembly- a further logistical challenge. The weight of the 21.5 ton safety coupling was further increased by the 3.5 ton heavy-duty transport frame. Once ready for shipment, the ground level low-loader had no width capacity to spare for the 1,500 kilometer journey. As this type of heavy-duty transport is not allowed on the motorways in France,the team of drivers took a total of three days to reach their destination. After intensive functional tests, the unit was shipped to Denmark for installation in the wind energy test facility whose motors have since then been protected by what is currently the largest safety coupling.

其他大容量安全型联轴器的试验项目

Rainer Benz 总结道:“我们对于这项富有挑战力的项目能够成功完成感到无比自豪。能够满足这些极端的特殊要求,只用了解整个过程并且同时能够正确地思考才能做到。”他的团队正在以世界上最大的联轴器申请吉尼斯世界纪录。由于这个项目的顺利完成,其他一些扭矩在百万牛米的研发项目也已经进入视线,这对于研发团队是真正意义上的认可。这些新项目的概念可参考最初的设计理念。这种可自由配置的研发过程确保了每个项目个人能力的展现和具体需求得到满足。

Pilot project forother high-capacity safety couplings

“We are obviously proud of the successful completion of this challenging project. These type of extreme demands can only be met by businesses who have an in-depth understanding of process whilst being able to think laterally at the same time,” concludes Rainer Benz. His team therefore sees the pending application for an entry in the Guinness Book of Records for the world's largest safety coupling as the icing on the cake. Other projects in the multi-million Newton meter range have already appeared as a result of this accomplishment, which is the real seal of approval for the development team. Concepts for these new projects can refer back to the initial design. This freely adaptable interface ensures the individual and specific demands of each project are met.